Table of Contents

Introduction to Pappedeckel

If you’ve come across the word Pappedeckel and wondered what it means, the answer is pretty simple. A Pappedeckel is a paper lid, commonly used to cover cups, food containers, and packaging. You’ll see it most often in cafés, takeaways, and eco friendly packaging solutions. While it may look like a small detail, it plays an important role in reducing plastic use and supporting more sustainable everyday choices.

What Is a Pappedeckel?

The word Pappedeckel comes from German. “Pappe” means cardboard or thick paper, and “Deckel” means lid. Put together, it literally means “paper lid.” Simple as it sounds, this small invention has become an important part of modern packaging, especially as businesses look for greener alternatives.

A Pappedeckel is usually made from pressed cardboard or sturdy paperboard and shaped to fit cups, takeaway containers, jars, or food packaging. Its main job is to create a secure cover helping prevent spills, keeping food protected during transport, and adding a layer of hygiene. Unlike plastic or metal lids, paper lids are lightweight, biodegradable, and recyclable, which makes them a popular choice for environmentally conscious brands and consumers.

What makes the Pappedeckel so effective is its simplicity. There’s no complex design or technology behind it just well shaped, durable paper. Even so, it manages to do a lot: it helps keep drinks warm, reduces mess from spills, protects food, and does all of this without harming the environment. Sometimes, the simplest solutions really do make the biggest difference.

Summary

Pappedeckel is a dense, smooth, fiber based board that stands apart from standard cardboard for its durability and finish, with roots in early papermaking and refined through modern manufacturing processes. Its production emphasizes quality fibers, precise sheet formation, rigorous testing, and growing innovations in recycling and energy efficiency. Widely used across packaging, bookbinding, crafts, education, furniture, and even industrial applications, it balances strength with aesthetics. Environmentally, it offers clear advantages through recycled content, biodegradability, energy efficient production, and a lower carbon footprint, supporting broader sustainability goals.

Historical Background and Evolution

Pappedeckel has roots that can be traced back to the early development of paper and board making processes. Initially, these materials were crafted by hand, using pulped fibers from textiles and plants. Over time, technological advancements streamlined production, improving consistency and quality. This evolution has led to the sophisticated manufacturing methods that produce pappedeckel today.

Early Beginnings: From Parchment to Paper

In ancient times, people relied on whatever materials were available to cover food and liquids. Parchment, waxed cloth, and natural plant wraps were commonly used. While these options helped to some extent, they weren’t very durable and often failed to keep moisture out. Still, they marked the first steps toward better protective coverings. As papermaking gradually spread from China to Europe during the Middle Ages, craftsmen began experimenting with thicker paper and pressed pulp, setting the stage for stronger paper based solutions.

The Industrial Revolution and the Rise of Cardboard

The biggest shift came with the Industrial Revolution in the 18th and 19th centuries. Cities were growing fast, and more people depended on takeaway food and drinks. This created a strong demand for packaging that was cheap, lightweight, and easy to produce in large quantities. Cardboard, developed in the early 1800s, quickly met these needs. It was affordable, easy to shape, and ideal for making simple lids and covers.

Germany’s Role in Making It Popular

Germany played an important role in bringing the Pappedeckel into everyday use. Known for its advances in packaging and manufacturing, the country embraced paper lids as café culture expanded in the late 19th and early 20th centuries. Paper lids proved especially useful for hot drinks and takeaway meals, and over time, the word Pappedeckel became closely associated with sturdy, practical, and environmentally friendly paper lids.

Resourcefulness During the War Years

During the World Wars, materials such as metal and plastic were in short supply, which pushed people to rely more heavily on paper based alternatives. Pappedeckel were used not just for drinks, but also as covers for ration containers and household storage. Their simplicity and usefulness made them a common item during periods when resources were limited.

The Post War Coffee Boom

After World War II, coffee culture took off across Europe and North America. Cafés became social hubs, and takeaway drinks grew in popularity. Paper lids fit perfectly into this lifestyle they were affordable, easy to use, and helped keep drinks warm while reducing spills. By the 1970s and 1980s, as fast food and café chains expanded worldwide, paper lids had become a standard part of food and beverage packaging.

The Modern Evolution of Pappedeckel

Today, the Pappedeckel represents more than convenience. It has become a symbol of sustainability and a practical response to the growing problem of plastic waste. Modern versions use recyclable materials, eco friendly coatings, and customizable designs, allowing them to meet today’s expectations without losing their original purpose. Despite all the improvements, the idea remains the same as it was centuries ago: a simple, reliable way to protect food and drinks.

Industrial Applications and Versatility

The industrial uses of this board extend beyond simple packaging. In construction, it serves as a lightweight yet strong material for temporary structures. In the automotive industry, it’s used for interior components due to its sound dampening qualities. This versatility highlights this material’s adaptability across a wide range of fields, where its unique properties can be maximized.

| Aspect | Pappedeckel | Cardboard |

|---|---|---|

| Base material | Fiber-based | Fiber-based |

| Density | Generally denser | Less dense |

| Strength & durability | More robust; suitable for applications needing extra strength and longevity | Adequate for lighter, everyday uses |

| Production quality | Often made with higher-quality fibers | Typically uses standard fibers |

| Surface finish | Smoother and more aesthetically pleasing | Rougher surface compared to pappedeckel |

| Typical use | Premium or strength-demanding applications | General packaging and common uses |

Pappedeckel in Everyday Life

Beyond industrial applications, this board finds its way into everyday life in unexpected ways. It serves as a base for puzzles, game boards, and even in some furniture designs. Its ability to be customized, printed on, and cut to size makes it a favorite among manufacturers of consumer goods, where the balance between strength and aesthetics is crucial.

How is Pappedeckel Made?

The manufacturing process of pappedeckel is key to its distinct characteristics. It involves several steps that ensure the material’s strength and durability.

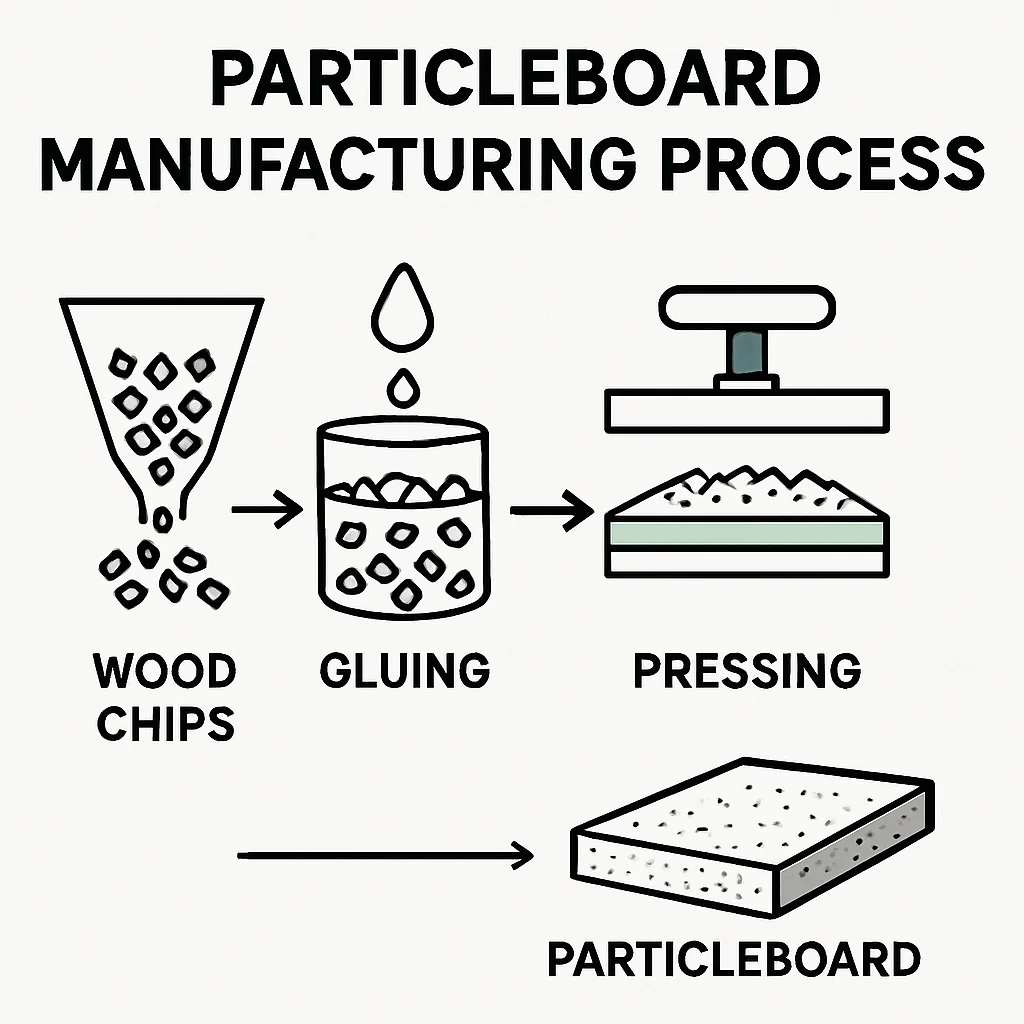

The Pappedeckel Manufacturing Process

The pappedeckel manufacturing process typically includes fiber selection, pulping, precise sheet formation, drying and finishing, and cutting.

- Fiber Selection: The process begins with selecting high quality fibers, usually from recycled paperboard or wood pulp. This choice not only enhances the final product’s quality but also contributes to environmental sustainability. The selection of fibers is critical, as it determines the texture and resilience of the final product, ensuring that it meets the demands of various applications.

- Pulping: The selected fibers are then processed into a pulp. This involves breaking down the raw materials into a fibrous mush, which can then be formed into sheets. The pulping process is meticulously controlled to maintain the integrity of the fibers while ensuring a uniform consistency, which is crucial for the strength of the final product.

- Sheet Formation: The pulp is spread out and pressed into sheets. During this stage, the thickness and density of the board are determined. Advanced machines help make sheets accurately. They can be customized for different needs, like strong packaging or fine art projects.

- Drying and Finishing: Once formed, the sheets are dried and finished. This step might include adding coatings or treatments to improve water resistance or surface smoothness. The finishing process is vital for enhancing the material’s durability and functionality, providing additional properties such as UV resistance or enhanced printability for marketing purposes.

- Cutting and Shaping: Finally, the sheets are cut and shaped according to their intended use, whether for packaging, book covers, or other applications. This stage involves sophisticated cutting technologies to ensure precision and efficiency, minimizing waste and optimizing the material for specific client needs.

Quality Control and Testing

Throughout the manufacturing process, rigorous quality control measures are implemented. Each batch of this material is subjected to tests for strength, moisture content, and surface quality. These tests ensure that the final product meets industry standards and specific client requirements, guaranteeing reliability and performance across all applications.

Innovations in Pappedeckel Production

The production of this board is continuously evolving, with innovations aimed at improving sustainability and efficiency. New techniques in fiber recycling and energy conservation are being integrated into production lines. These advancements not only enhance the quality of the material but also contribute to reducing the environmental footprint of its manufacturing process.

Uses of Pappedeckel

Common pappedeckel uses include robust packaging, durable book covers, and creative craft bases, thanks to its strength and smooth surface.

Packaging Industry

In the packaging industry, this material is often used for creating robust and reliable packaging solutions. Its durability ensures that products are well protected during transportation and storage. Companies favor it for its ability to withstand pressure and impact, reducing the risk of damage to contents and thereby ensuring customer satisfaction.

Bookbinding

The smooth surface and rigidity of the board make it an excellent choice for bookbinding. It provides a sturdy cover that withstands wear and tear, ensuring longevity for books. Publishers and artisans alike appreciate its ability to hold up against repeated handling, making it ideal for high quality, long lasting publications.

Craft and Art Projects

Artists and crafters appreciate this board for its versatility. It can be easily cut, shaped, and painted, making it an ideal base for various creative projects. Its compatibility with different media, from paints to adhesives, allows artists to explore diverse techniques, pushing the boundaries of creative expression.

Educational Tools

In educational settings, it is used to create durable and interactive learning materials. From flashcards to educational games, its robustness ensures longevity, even with frequent use by young learners. Educators value it for its tactile qualities, which enhance sensory learning experiences.

Furniture and Interior Design

Its rigidity and lightweight properties make it a valuable material in furniture design. Designers use it to create innovative, eco friendly furniture pieces that are both functional and aesthetically pleasing. Its ease of customization allows for unique designs that can be tailored to specific tastes and spaces.

Environmental Benefits of Pappedeckel

Why choose Pappedeckel over alternatives?

Pappedeckel stands out as a practical and sustainable alternative to traditional lids. It is recyclable, lightweight, easy to store, cost effective in bulk, and ideal for branding with custom prints or logos.

Comparison: Pappedeckel vs Plastic and Metal Lids

| Feature | Pappedeckel (Paper Lid) | Plastic Lid | Metal Lid |

|---|---|---|---|

| Material | Recycled cardboard or paper | Petroleum based plastic | Aluminum or steel |

| Eco-Friendliness | Biodegradable and recyclable | Non biodegradable, causes pollution | Recyclable but requires high energy |

| Durability | Moderate; suitable for short term use | High; water resistant and long-lasting | Very high; heat and water resistant |

| Cost | Low to moderate; affordable in bulk | Very low; cheapest in mass production | High; expensive to manufacture |

| Heat Resistance | Moderate; may need coating for hot drinks | Good; handles hot and cold beverages | Excellent; withstands high temperatures |

| Weight | Lightweight and easy to transport | Very light | Heavier than paper or plastic |

| Branding Options | Easy to print and customize | Limited branding options | Limited; requires special printing |

| Environmental Impact | Very low; supports sustainability | High; plastic waste and microplastics | Medium; mining and smelting impacts |

| Best Use Case | Coffee cups, takeaway food, eco packaging | Mass market drinks and cheap containers | Premium packaging and canned foods |

As sustainability becomes a priority, the environmental benefits of pappedeckel are increasingly significant. Here’s why this material is considered an eco friendly option:

Use of Recycled Materials

It often incorporates recycled fibers, reducing the demand for virgin materials. This approach not only conserves natural resources but also minimizes waste. By utilizing post consumer waste, the industry significantly reduces its environmental impact, contributing to a circular economy.

Biodegradability

Unlike some synthetic materials, it is biodegradable. This means that it can break down naturally over time, reducing its impact on landfills and the environment. Its ability to decompose without leaving harmful residues makes it a preferred choice for environmentally conscious consumers.

Energy Efficiency

The manufacturing process of this board is generally less energy intensive compared to other materials. This efficiency further enhances its status as an environmentally friendly option. By optimizing energy usage, manufacturers are able to reduce greenhouse gas emissions and lower the overall carbon footprint of production.

Comparison with Other Materials

When compared to plastics and other non fiber based materials, this material boasts a significantly lower carbon footprint. This makes it a preferable choice for businesses and consumers aiming to reduce their environmental impact. Its life cycle assessment shows favorable results in terms of energy consumption and emissions, reinforcing its reputation as a sustainable material.

Contribution to Sustainable Development

This board supports sustainable development goals by promoting responsible consumption and production. Its use aligns with global efforts to reduce waste and foster sustainable practices. By choosing it, businesses can demonstrate their commitment to sustainability, enhancing their brand image and appeal to eco conscious consumers.

Conclusion

Pappedeckel is more than just a variant of cardboard; it is a versatile, durable, and eco-friendly material with a wide range of applications. Whether used in packaging, bookbinding, or artistic endeavors, its benefits are clear. As awareness of environmental issues grows, materials like pappedeckel will likely play an increasingly important role in our lives.

By understanding what pappedeckel is and how it compares to other materials, individuals and businesses can make informed choices that support sustainability. As we move towards a greener future, every choice counts, and adopting materials like this board is a step in the right direction. Its potential to drive positive change in both consumer habits and industrial practices underscores its significance in the journey toward a sustainable future.

Frequently Asked Questions

Question: What is pappedeckel, and how is it different from standard cardboard?

Short answer: Pappedeckel is a dense, smooth, fiber based board known for greater durability and a finer surface finish than typical cardboard. While both are fiber based, it often uses higher quality fibers and more precise manufacturing, making it better suited for applications that demand strength, longevity, and an aesthetically pleasing surface.

Question: How is pappedeckel made?

Short answer: It’s produced through a controlled, multi step process: selecting high quality fibers (often recycled or wood pulp), pulping them, forming and pressing sheets to the required thickness and density, drying and finishing (with optional coatings for water resistance, smoothness, UV resistance, and enhanced printability), and finally cutting and shaping to specifications. This workflow gives the material its strength, consistency, and refined finish.

Question: Where is pappedeckel used?

Short answer: Its versatility spans both industry and everyday products. Common uses include robust packaging, durable book covers, craft and art bases, educational tools (like flashcards and games), and lightweight furniture or interior elements. Industrially, it’s used for temporary construction structures and automotive interior components, where its rigidity and sound dampening qualities are valuable.

Question: What are the environmental benefits of pappedeckel compared to other materials like plastics?

Short answer: It often incorporates recycled fibers, supports a circular economy, and is biodegradable, reducing landfill impact. Its production is generally less energyin tensive, lowering greenhouse gas emissions. Compared with plastics and other non fiber materials, it typically has a smaller carbon footprint, with life cycle assessments showing favorable energy and emissions profiles. It also aligns with broader sustainability goals around responsible consumption and production.

Question: Can pappedeckel be tailored for specific performance, and how is quality ensured?

Short answer: Yes. During finishing, coatings and treatments can add water resistance, improve surface smoothness, enhance printability, and provide UV resistance. Manufacturers control sheet thickness and density during formation for targeted performance. Throughout production, rigorous testing for strength, moisture content, and surface quality ensures consistency and reliability across applications.

We’ll keep you updated, just stay in touch! Blog Discover by Rank Wox!